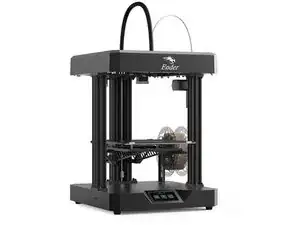

Introduction

Tools

-

-

If the Z-axis is no longer working.

-

disconnect the power cable to the printer and open the bottom and on the mother board switch the cable to Z-step motor with the one to the extruder step-motor.

-

close the bottom and start the printer in setting mode.

-

request the extruder to move forward a little, and if the Z-motor move, you can confirm the Z-motor is working as expected.

-

You can order a new driver online.

-

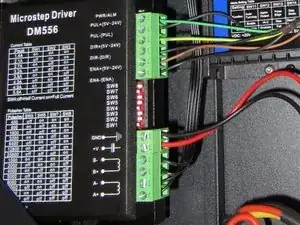

I choose a DM556, because it is cheaper than the DM542.

-

-

-

Disconnect the power cable again and open the bottom of the printer

-

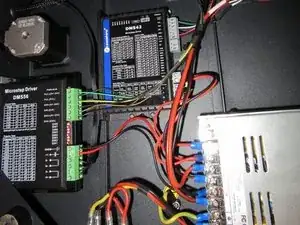

There is enough space to place the driver as on the picture.

-

You need to drill two hole in the frame on the back for the two screws to hold the driver.

-

Take you time to mark where you need to drill as it will be visible from the outside later.

-

-

-

Connect the power directly to the 12V power supply.

-

Cut the cable to the Z-axis at approx 15cm from the plug of the motherboard.

-

Save the 15cm left!

-

Connect the A-, A+, B- and B+ to the right place.

-

Use as much as possible the X and Y connection as a reference to connect the Z!

-

-

-

Use new wires to connect the control signals from the mother board to the external driver.

-

Carry over the way is is connected on X and Y.

-

use later zip-tie to prevent all the cable you add to move and vibrate when the printer will be running.

-

-

-

The whole idea is to bypass the original onboard driver (which is under dimension, I think).

-

You can remove the mounting screws of the motherboard to remove the connector and reuse it on the similar position as X and Y.

-

OR you can simply solder the each wire, one by one.

-

-

-

I selected 2,1A: SW1=off SW2=on SW3=on.

-

I selected 3200pulses/rotation: SW5=on SW6=on SW7=off SW8=on to match the the movement of the printing surface.

-

You can close the bottom of the frame and connect back the power cable to give a try!

-

One comment

I’m having an issue with my X-Y motors one of the stepper boards gave out and I bought two of these as a replacement where would I start