Introduction

Please make sure you disconnected the hose and unplugged the power cord before attempting any case opening. Make sure the additional tank is emptied.

-

-

Disconnect the hose of the external tank.

-

Unsnap the power cord from the casing.

-

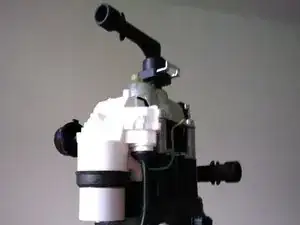

Release the high pressure unit from the housing.

-

-

-

Pull the metal clips that hold the pipes in place with pliers.

-

Once released, put the pipes and clips aside. Make sure you don't lose the seals.

-

-

-

With the use of a Philips screwdriver release the earth connector from the metal flange.

-

Carefully loosen each of the 4 screws that hold the flange attached to the high-pressure chamber of the pump.

-

Before to completely release the flange and the head of the pump hold the flange firmly with your other hand or ask a friend for help. Springs inside the pump push hard.

-

-

-

Firmly hold the piston guidance.

-

In order to protect the inside of the pump from dust, reposition the 4 screws to hold the piston guidance in place.

-

-

-

Check that you have in hand all these parts before to assemble the new head.

-

The spare part 9.001-216.0 : the head of the high-pressure chamber.

-

The triangle-shaped seal: this part has been previously removed from the to-be-replaced head.

-

The white pipe to connect the pump to the external tank: this part has been removed from the head to be replaced.

-

The control piston and its spring picked from the head to be replaced. The control piston acts on an external switch which electrically commands the start of the washer.

-

The red suction part retrieved from the head to be replaced.

-

The injector removed from the head to be replaced.

-

-

-

Insert the control piston into the hole circled in red.

-

Place the cleaning material after inserting the control piston. The white pipe must be placed exactly in the same position as shown in the picture.

-

-

-

Put the metal flange on the head.

-

Retrieve the four screws that hold the pistons in place. The springs of the piston push hard outward: firmly hold them in place while you bring and put the head in place.

-

Start mounting two diagonally opposite screws.

-

Finish mounting the two other screws

-

-

-

Jiggle the electrical unit of the pump.

-

Stop jiggling the electrical unit after you hear a 'click'.

-

-

-

Make sure that the earth connection is screwed to the metal flange of the head BEFORE any electrical testing.

-

Only after that you may briefly test the start of the pump.

-

-

-

Make sure you did not lose the small-sized seal of the high-pressure pipe.

-

Remount the seal inside the pipe before remounting the pipe on the high-pressure unit.

-

-

-

Place the pipes in the same position as shown in the pictures.

-

Push the metal clips to hold the pipes in place.

-

-

-

Carefully reposition the high-pressure unit into the casing of the washer.

-

It must fit gently into the casing . No need to force the fitting.

-

To reassemble your device, follow the instructions of the casing tear-down in the reverse order.